|

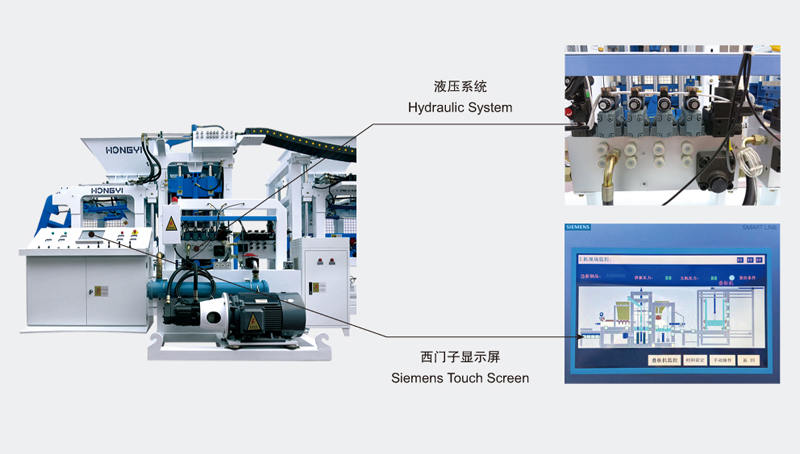

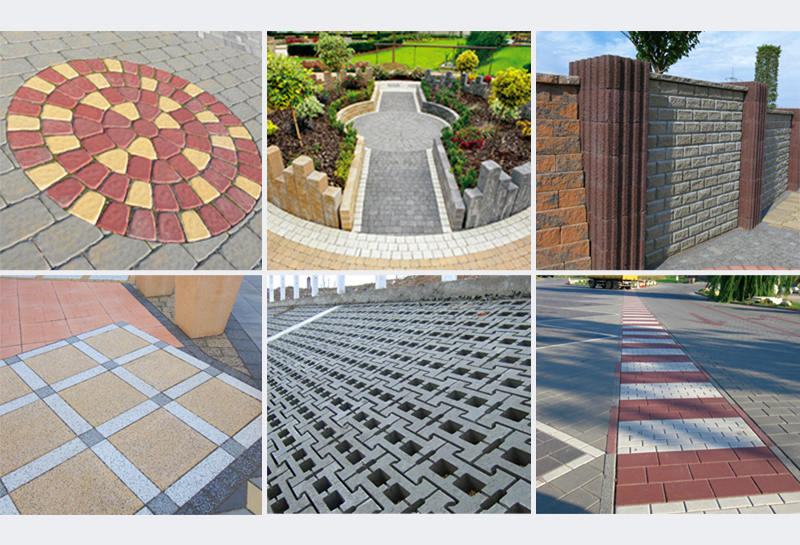

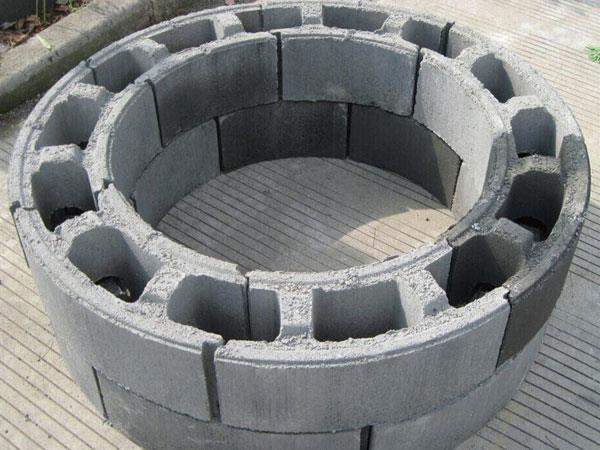

T1500 block making machine can realize the layered material displacement for the production of building block, municipal pavement brick, pc floor tile, high-end stone-imitation floor tile, water conservancy revetment block and other products. Configuration characteristics: 1. The main body of T1500 block making machine is made of high-strength section steel and wear-resistant steel plate. 2. This machine adopts the touch screen panel of Siemens interface and is configured with data one-key recovery of factory settings and remote fault diagnosis function and so on; 3. The super-capacity pump station and high-efficient cooling system can reduce the rise of oil temperature and make the machine have higher working frequency; 4. Two oil pumps are connected to each other and work at the same time. The proportional valve and digital integrated electronic module control their operation and make the operation more convenient; 5. The forced horizontal material displacement mechanism can realize active arch-broken material displacement, flatten the materials and feed the materials into the mould cavity; 6. This block making machine has automatic height adjustment device, which can easily and simply adjust the height when producing products of different thickness. 7. The pneumatic scraper of the backing material displacement mechanism can automatically adjust the scraping action along with the movement and can clean up the residual materials on the mould plane. Meanwhile, it can reduce the wear of mould frame and can avoid that the residual material stacking and mixing affect product quality. 8. Silo position control unit can ensure the automation and accuracy of material quantity and supply. 9. The mould frame adopts air bag elastic device, which can make dynamic self-adaptive adjustment and short-term locking, reduce the damage of vibration to the machine and improve the compacting effect. 10. Schneider frequency conversion vibration technology and multi-axis and multi-point vertical synchronous vibration technology can obtain high-strength excitation force and compaction efficiency and can quickly and evenly compact materials to get high-level products. |

| Overall dimension |

6580×2170×3100mm |

Vibration method |

Table mould resonate |

| Pallet size |

880×880×20mm(PVC)

|

Vibration frequency |

50-70hz |

| Working area |

800×800mm |

Installed capacity | 56.1kw |

| Machine weight | 12000kg | Circle time |

15s-25s Depending on the product size |

|

Specification of products(mm) |

Number of blocks per pallet |

Pieces/1 hour |

Pieces/8hours |

Pieces/300 day(two shifts) |

||

| Block |

|

400×200×200 390×190×190 |

8 | 1,920 | 15,360 | 9,216,000 |

|

Hollow Brick |

|

240×115×90 |

18 | 4,320 | 34,560 | 20,736,000 |

|

Paving Brick |

|

225×112.5×60 |

18 | 4,320 | 34,560 | 20,736,000 |

| Floor Brick |

|

200×100×60 |

28 | 6,720 | 53,760 | 32,256,000 |

|

Standard Brick |

|

240×115×53 |

36 | 8,640 |

69,120 |

41,472,000 |

REQUEST A FREE QUOTE

Please fill in your info and we will contact you soon.

Series products

Never cease in exploring and innovating