|

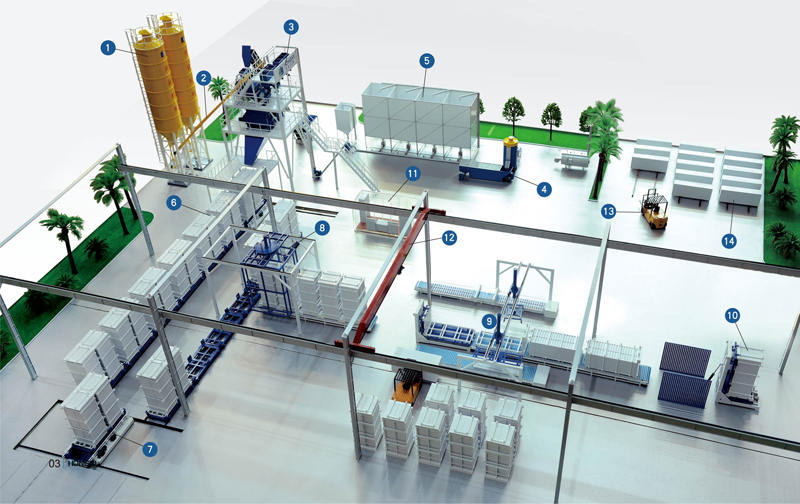

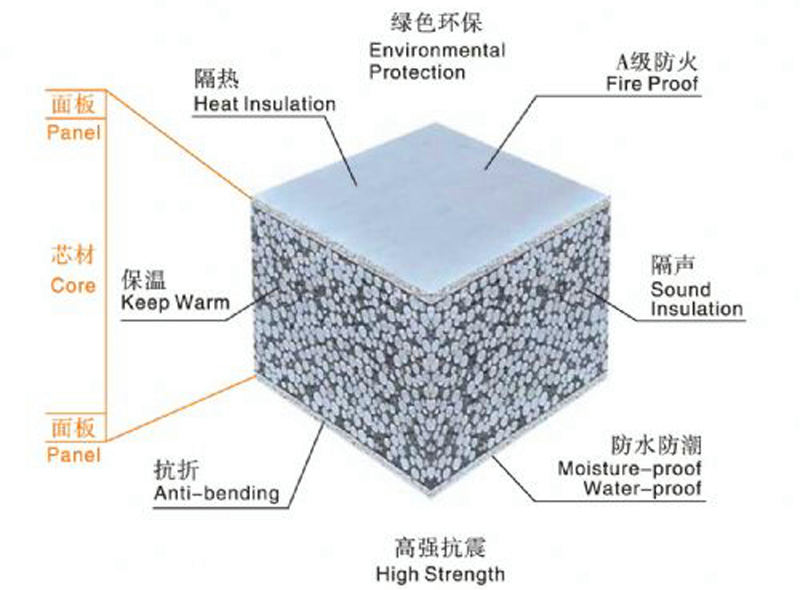

Introduction The vertical sub-master mould and master mould composite light-weight wall panel production line uses sub-master mould and master mould to perform the cycle production of full-automatic molding and curing. The raw materials used can be EPS particles, XPS particles, ceramisite, modified perlite and other light-weight materials. The finished product is light-weight composite heat preservation wall panel. This production line is composed of full-automatic batching machine, material metering and conveying equipment, continuous mixing station and material filling system, sub-master mould and master mould carriage, shuttle vehicle, upender, demolding machine and so on. Characteristics Due to the detachable design of sub-master mould and master mould, the master mould can be online while the sub-master mould can be concentrated in the curing room for curing, and the master mould can support the intermittent running of other sub-master moulds. In this way, large capacity can be realized on the limited site by avoiding the constraints and limitations of online curing on site and production scale. Configuration introduction 1.Vertical: vertical mould and mould vertical grouting 2.Sub-master mould and master mould (also known as sub-master mould and master mould carriage): here sub-master represents the module and master represents the mould moving carriage. 3.One set of sub-master mould and master mould carriage contains two sub-master moulds and one mould moving carriage. 4.Automatic mould turnover platform 5.Special mould removing mechanical device |

REQUEST A FREE QUOTE

Please fill in your info and we will contact you soon.

Series products

Never cease in exploring and innovating